Draft Report submitted to the

California Alfalfa Seed Production Research Board

February 1, 2000

Stephen S. Peterson

Introduction

Alfalfa seed producers in the San Joaquin Valley have begun using a new technique to acidify soil and clip back their alfalfa at the same time. Sulfuric or phosphoric acid started to be commonly used for this purpose around 1996. Depending on the amount of alfalfa growth, 300 to 600 lb. per acre is applied when alfalfa is normally clipped back (i.e. February to March). Phosphoric acid has the additional benefit of adding phosphorus to the soil, and it is less corrosive.

While this practice is becoming more common in seed production, there is little data to support its efficacy in alfalfa seed. Growers needed more information regarding the advantages and disadvantages of using acid on alfalfa. Data is scarce on how this product affects alfalfa growth, seed yield and soil properties. Also, there may be side effects of this product on insects that indirectly affect yield. The purpose of this study was to survey fields that have been treated with sulfuric or phosphoric acid and measure the effect on soil pH, soil salinity, arthropod pests, and yield.

Materials and Methods

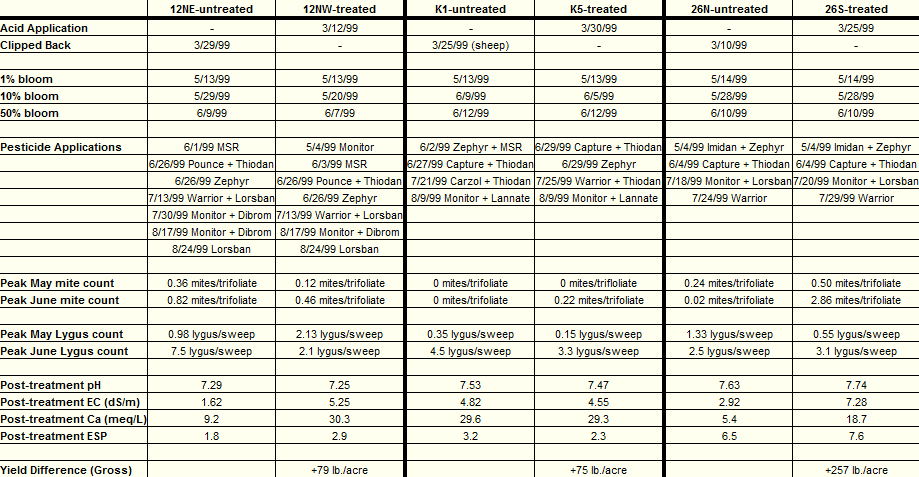

Three pairs of established alfalfa seed fields were selected for this survey. The first pair was located 1.4 miles south of Mendota on the Silveira Bros. Ranch, in Fresno County. Field 12NE was not treated with acid while 12NW was treated with 550 lb./acre of sulfuric acid on March 12, 1999. Both fields were planted with the same cultivar. 12NW had been planted in fall of 1996, while 12NE had been planted in fall 1997.

The second pair of fields was located 5.7 miles west of Tranquility and managed by Yribarren Farms, in Fresno County. Field K1 was untreated while K5 was treated on March 30, 1999 with 680 lb./acre of sulfuric acid. Field K1 was planted in January of 1998, while field K5 was planted in October of 1997. These fields were different cultivars.

The third pair of fields was located 14 miles south of Corcoran on the Homeland Ranch of J.G. Boswell Co., in Kings County. Field 26N was not treated, while field 26S was treated on March 25, 1999 with 600 lb./acre of sulfuric acid. Both fields were planted in 1998, but were different cultivars.

Sweep samples were taken weekly from March through June to monitor populations of Lygus hesperus (Lygus). At least four sets of sweep samples were taken from different areas of each field. Sample size varied from 2 to 20 sweeps per set, depending on pest density. Lygus nymphs and adults were counted in the field. Leaf samples were collected at the same time to monitor spider mite populations, Tetranychus spp. Mite leaf samples (13 trifoliates per site) were collected at the four sweep sample sites. Leaves were chosen at random from the top, middle, and bottom of the plant. The four samples were combined and placed in a paper bag in an ice chest, and transported back to the workshop. From each field, 50 trifoliates were examined under a dissecting microscope at 10X, and adult, motile spider mites were counted.

Two soil samples were taken from each field. A minimum of 10 soil cores, one-inch diameter and 12 inches deep, from four sites in each field made up each soil sample. The first sample was taken prior to the acid application in the Yribarren and Homeland fields. The first soil sample was taken 7 days after the application in the Silveira fields. The second set of soil samples was taken 45 to 50 days after the acid application. Mid-State Laboratory, LLC, in Visalia, California, analyzed the soil samples. Data on pH, electrical conductivity, cation levels, exchangeable sodium percentage, and lime levels were collected.

Growers provided gross seed yield data for each field at the end of the season

Results

Sulphuric acid applied to growing alfalfa at 550 to 680 lb./acre in mid to late March was extremely effective as a clip back. Plants immediately died back to the crown, but the plants regrew quickly and vigorously in all treated fields.

Acid dissolves lime in the soil, which can increase calcium (Ca) levels. In this way, lime acts as a buffer to soil pH changes. All of the fields in this study showed high lime levels. Calcium levels were much higher in 12NW (treated), after the acid application (Table 1). K5 (treated) started with lower Ca levels, and after treatment reached a level similar to K1 (untreated). Field 26S (treated) started with Ca levels higher than 26N, and this level decreased somewhat after treatment.

With the high lime levels found in the study fields, it is not surprising that the acid treatments had very little effect on soil pH. In the post-treatment soil samples, pH readings were very similar in each pair of fields (Table 1).

Soil salt content is measured by electrical conductivity (EC) and it is recommended that EC’s should be kept below 4.0 dS/m. EC levels were above 4.0 in field’s 12NW, K1 and 5, and 26S. In field’s 12NE and 12NW, EC was lower in the 12NE (untreated) for both soil samples. K1 had a much higher EC compared to K5 prior to the acid treatment. EC rose in K5 after the acid treatment to a level similar to K1. Field 26S (treated) had much higher EC readings than 26N both before and after acid treatment. EC appeared to increase at the post treatment soil sample in all three of the acid treated fields.

Exchangeable sodium percentage (ESP) measures the amount of sodium that can be exchanged with calcium. ESP measurements greater than 10 is an indicator of alkali soils. None of the fields sampled would be considered alkali soils. ESP levels were higher in two of the three acid treated fields (12NW and 26S) post-treatment. In field K5 (treated), ESP was lower than in K1 after treatment.

In May, Lygus populations reached higher levels in 12NW (treated) compared to 12NE (Table 1). However, in June Lygus counts peaked at much higher levels in 12NE (untreated). Both 12NE and 12NW required six insecticide applications. In fields K1 and K5, Lygus counts were higher in K1 (untreated) in both May and June. Field K1 (untreated) required four insecticides applications, while K5 needed only three insecticide applications. In field’s 26N and 26S, Lygus populations were higher in 26N (untreated) in May, but higher in 26S (treated) in June. Both 26N and 26S required four insecticide applications.

Mite peak populations were higher in both May and June in field 12NE (untreated) compared to 12NW (treated)(Table 1). In field’s K1 and K5 mite counts remained at zero in May. In June, field K5 (treated) showed some mites while K1 was still at zero. In field’s 26N and 26S mite population peaks were higher in field 26S (treated) in both May and June. Each field in this study was treated with one miticide application during the season.

In the three pairs of fields, gross yields were higher in the acid treated compared to the untreated fields. In field 12NW there was 79 lb./acre more seed compared to 12NE, in field K5 there was 75 lb./acre more seed compared with K1, and in 26S, there was 257 lb./acre more seed compared to 26N. These differences should be interpreted with caution, considering that in K1 and K5, and 26N and 26S, different cultivars are compared.

Discussion

The sulfuric acid treatments examined in this study were highly effective at stopping alfalfa growth without killing the plant. The fields examined in this study had high levels of lime, which buffered the effect of the acid on the soil’s pH. Calcium levels appeared to increase in two of the three fields after the application, while the third field already had high calcium levels. Salt content, or EC, appeared to rise with the application of acid. There was no clear trend in Lygus sweep counts. Acid did not appear to reduce populations of Lygus for any length of time. The same is also true with spider mite populations. In one of the acid treated fields, spider mite populations were consistently higher than in the untreated field. Gross yields were slightly higher in two of the three treated fields, and much higher in one treated field; however, yield differences may be due to different cultivars rather than acid treatment.

Acknowledgements

I want to thank Tim Sherrill, Darrell Silveira, Robert Sheesley, and Jeff Yribarren for allowing their fields to be part of this survey and for providing valuable information. I also want to thank Shannon Mueller for many helpful suggestions. This project was made possible with funding from the California Alfalfa Seed Production Research Board.

Table 1. Effect of Sulfuric Acid on Alfalfa Seed Production, 1999.